diy autoclave carbon|sterilization using pressure cooker autoclave : fabrication Video tutorial providing a complete introduction to working with out-of-autoclave prepregs. . This whitepaper addresses the applications where the RFID tag will face high temperatures, autoclave processes, harsh cleaning cycles, and automotive manufacturing processes.

{plog:ftitle_list}

Repeatedly autoclave instruments and labware with these autoclavable polypropylene pans, featuring heavy-duty construction.

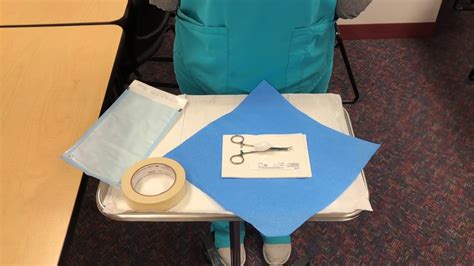

wrapping surgical instruments for autoclave

you have at your disposal three pipette

sterilize instruments before autoclave

I need an autoclave for carbon fiber parts. Unfortunately, I don't have 0k for an off-the-shelf (or even used) model. I have seen somewhere on the web, a guy who made a small autoclave out of an air-tank.21 page tutorial guide with lots of detailed photographs throughout explaining the complete .Video tutorial providing a complete introduction to working with out-of-autoclave prepregs. .

100% Carbon fiber prepreg intake velocity stacks ducati 888/851Testing new prepreg tooling moulds out in my autoclave.Seems to work perfect. molds are made m. 100% Carbon fiber prepreg intake .TIL you can make DIY carbon fiber parts or repairs fairly simply, even curing at room temperature without an autoclave . . I had a vendor line a small room with foil and use ceramic space heaters to cure honeycomb panel adhesive in lieu of an autoclave before lol. Totally worked Sticky Fingers: DIY carbon fiber Fake trim is for the birds. Of course, there are cost considerations, and a piece of lower-cost injection-molded plastic is a lot cheaper than actual wood, metal .

The XC110 Pre-preg is specially designed to be processed out of autoclave under vacuum in an oven and thus would give much better surface results than a typical autoclave pre-preg processed in this way. The first stage is to make accurate templates. The quickest and easiest way to do this is to use masking tape. #diy #composites #carbonfiber #carbon #autoclave #motorcycle #automobile#carbonfiber #diy #sbk #bmw #carbonparts #bike #frp #forgedcarbon

you need to pipette 50ul which pipette should you use

If you try to lay the carbon fiber early, the epoxy won’t be sticky enough and the carbon won't stay put. Too late and the carbon won't adhere at all. I've found the best solution is a combination of both. Laying a base layer of black-tinted epoxy, letting it dry to a tack and then using spray adhesive to help fix the carbon fiber into place. An autoclave delivers perfect surface quality of carbon fiber prepreg parts because of high (up to 8 bar) pressure that compresses the part and prevents air voids from forming. Some companies try a workaround and instead of curing prepreg parts with 6-8 bar pressure (autoclave curing) they simply put the parts in 1 bar vacuum in the oven. I got this made at local metal working shop.Its a new compressor tank 165cm long 80cm diameter.The rings are 3cm thick each site Next is putting in the heate. Honda Monkey R varbon fiber fuel tank.First and only one in the world I can find full carbon fibre Honda monkey R !!!!!!!!! Tank isnt clearcoated yet finish .

The Autoclave Myth. . It was used to make many parts from carbon-epoxy that were cured at 250 degrees. As the defense industry expanded their use of composite parts, they found that they needed laminates that would stand up better in what they call a "hot-wet environment." This is an environment where liquids such as jet fuel or exhaust at . 500 lbs of epoxy/carbon laminate from 70F to 200F at 1 degree per minute takes 2088 watts ; . For all but the best and most well designed “DIY” ovens, it is always wise to have somebody around when things are hot. . but autoclaves have other sources of drama! Exhaust gasses from combustion are a serious danger. Gas heaters need to be . Autoclave-less carbon fiber? Post Sat Nov 17, 2012 12:46 pm. . Incorrect wetting out of the fabric or core with the resin also can be an issue when your DIY’ing. Last edited by aussiegman on Mon Nov 19, 2012 6:35 am, edited 4 times in total.

Autoclave is a device for curing carbon fiber resin matrix composite products, which has five functions of heating, heat preservation, cooling, pressurization and vacuuming. The products made with it have low porosity and good quality consistency. In this article, the editor will tell you about the autoclave forming process of carbon fiber composite materials.

How to Fabricate Automotive Fiberglass & Carbon Fiber Parts PDF By:Daniel Burrill,Jeffery ZurschmeidePublished on 2012 by CarTech IncWhether repairing existing components, fabricating new ones, building a race car, or restoring a classic, this is the one book to guide the reader through each critical stage.This Book was ranked at 35 by Google Books for keyword .

CAUTION: Working with Carbon Fibers are EXTREMELY hazardous. Usage of proper breathing apparatus and body coverall is a MUST. Don't take RISKS!Everything DIY.

Whatever the reason, an autoclave can be a valuable tool for a prepper. Types of Homemade Autoclaves. There are three types of DIY autoclaves that you can make at home: pressure cookers, Instantpot cookers, and DIY large autoclaves. Pressure Cookers. Pressure cookers are a type of pressure pot that can use steam to sterilize equipment.

Illustration showing laminate orientation . Evolution of Processes and challenges. Within the past decade or so a different processing method has been gaining in popularity; Out Of Autoclave (OOA) vacuum curing and Vacuum Bag Only (VBO) curing. These methods can offer some benefits over the autoclave process based lower initial capital and long term operating . How to make carbon prepreg parts at home ( build autoclave ! ) Home made autoclvave for prepreg carbon at home.After alot of work the autoclave is almost re. Can you distinguish between dry carbon and wet carbon? What is the difference between their production processes? This video captures the production process . As promised here is the carbon fiber lamination DIY details. As you may already know, I have laminated Saya (my Continental GT650) in carbon fiber. . I was always under the impression that we need a Vacuum autoclave to work with Carbon Fiber. (2) Thanks 5th February 2021, 09:04 #3: GTO. Team-BHP Support . Join Date: Feb 2004 .

Me dice mi amigo Santiago que necesita un sistema de control para poder fabricar piezas de fibra de carbono para sus aviones. El proceso de fabricación necesita unas condiciones de presión y temperatura determinadas además de controlar los tiempos de curado, básicamente consiste en preparar los perfiles del ala y forrarlos con las capas de fibra de carbono, resina y kevlar, .

#carbonfiber #prepreg #brakecooling* The prepreg carbon fiber fabrics in this video were offered by HANKUK CARBON *How to Bake Prepreg Carbon Fiber Brake Coo.OL. Several intermediate modulus carbon fiber matrix composites were fabricated and tested. Four polymer matrix carbon fiber composites were evaluated for this comparative study: two autoclave carbon fiber epoxy composites (IM7/8552-1 and IM7/977-3) and two OOA carbon fiber epoxy composites (IM7/MTM45-1 and T40-800b/5320).Many OOA alternatives carry a higher risk of air-voids and require more time and effort to develop foolproof curing methods. In contrast, carbon fiber autoclaves operate at high-pressure and can still guarantee a complete vacuum on the part. The pressure is vital for manufacturing polymeric composites because it consolidates the prepreg plies to form a solid, strong material.

Carbon fiber is gaining popularity in the creation of bicycles, airplanes, and even some automobiles because it is both sturdy and lightweight. . DIY; Plastic; Working with Plastic; How to Make Carbon Fiber. Download Article. Explore this Article. . You need an autoclave or other heat source for the curing process. Advertisement. Method 3 .Prepreg carbon fiber making. #autoclave #carbonfiber #sportbike #diy #superbike

Product links https://www.easycomposites.co.uk/learning/low-melt-metal-core-mouldingFurther information In this composites training video, we demonstrate .

Graphene is one atom thick carbon stronger than steel, a whole new industry. Report comment. Reply. gerry says: September 11, 2015 at 6:23 am . Jan on Building A DIY Nipkow Disk Display; Jan on .

Over the past decades, LBBC Technologies has continually strived to push the boundaries of pressure vessel and autoclave design; through precision engineering, advanced technologies and electronic intelligence.

diy autoclave carbon|sterilization using pressure cooker autoclave